Advanced Steam Reducer in the GB-SPZ1400-1750PT EPS Machine

Advanced Steam Reducer in the GB-SPZ1400-1750PT EPS Machine

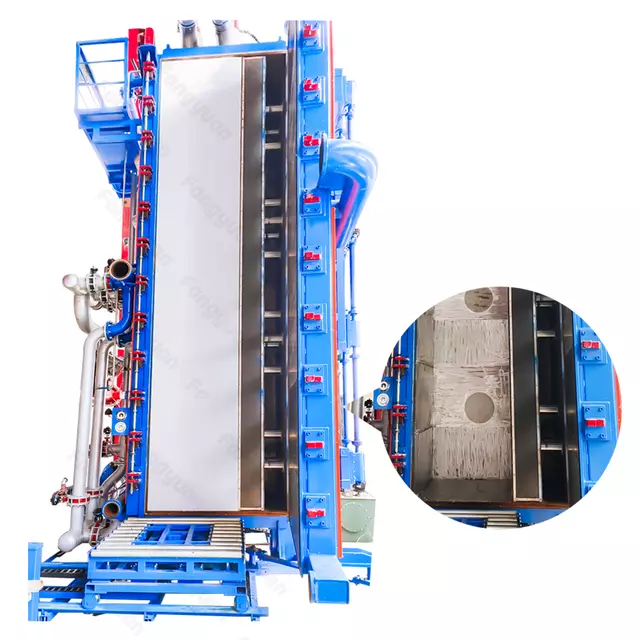

Overview

The GB-SPZ1400-1750PT EPS Machine is equipped with a GP1000 steam reducer, ensuring precise steam control. The SPZ2300 model features DN80 + DN32 cylinder valves with PID control, allowing for accurate steam pressure settings.

Key Features

GP1000 Steam Reducer: Provides precise steam control.

SPZ2300 Model: Features DN80 + DN32 cylinder valves.

PID Control: Ensures accurate steam pressure settings.

Electrical PID Pressure Setting: Enhances the accuracy of the steaming process.

Product Parameters

Steam Reducer: GP1000

Valves: DN80 + DN32 cylinder valves

Control System: PID control

Pressure Setting: Electrical PID

Use Cases

EPS Foam Packaging: Ideal for producing high-quality foam packaging for fragile items.

Custom Molds: Suitable for creating custom molds for automotive parts, construction materials, and insulation.

Benefits for Businesses

Precision: PID control ensures accurate steam pressure settings.

Reliability: Precise steam control enhances the quality and consistency of foam products.

Efficiency: Accurate steam pressure settings reduce energy consumption.

.jpg)

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

Expansible polystyrene EPS expanded machineryOct,14,2024

Expansible polystyrene EPS expanded machineryOct,14,2024 -

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Links

Links