How an EPP Shape Machine Works to Mold Custom Parts

Oct,27,2024visited: 145

2: How an EPP Shape Machine Works to Mold Custom Parts

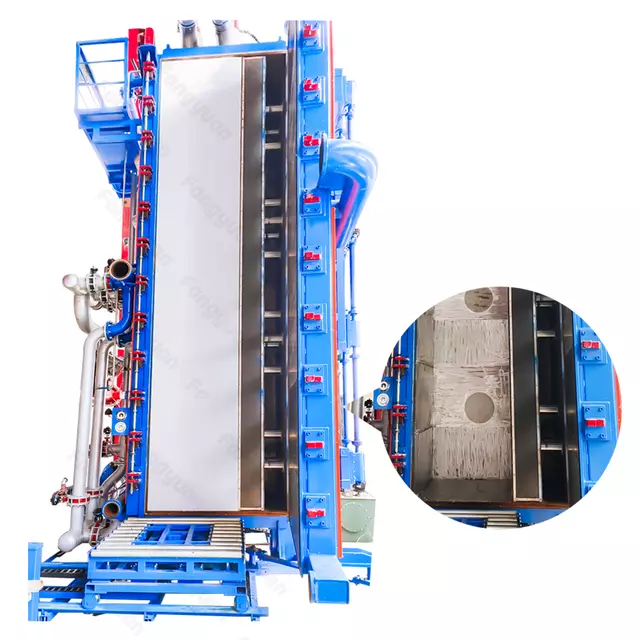

The EPP Shape Machine is essential for creating parts out of expanded polypropylene (EPP). It’s a specialized machine that forms lightweight, impact-resistant, and flexible products by heating EPP beads and injecting them into molds.

Here’s how it works: first, the EPP beads are expanded through heat, making them ready for molding. Next, the machine injects these beads into a mold where they take on the desired shape. After cooling, the final product is complete. This method is widely used for crafting custom parts that are strong yet lightweight.

.jpg)

How an EPP Shape Machine Works to Mold Custom Parts

end

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

Expansible polystyrene EPS expanded machineryOct,14,2024

Expansible polystyrene EPS expanded machineryOct,14,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Links

Links