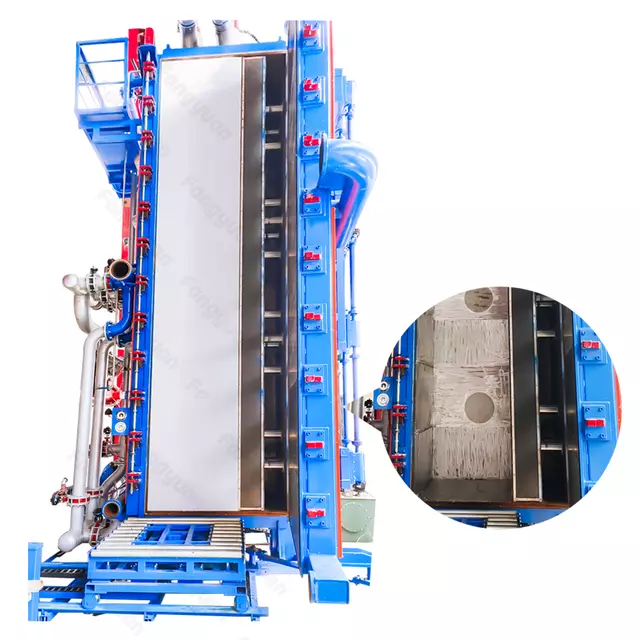

Sealing System in the GB-SPZ1400-1750PT EPS Machine

Sealing System in the GB-SPZ1400-1750PT EPS Machine

Overview

The GB-SPZ1400-1750PT EPS Machine features a robust sealing system with all fast plugs closely sealed using liquid sealant. The PU pipes are replaced by nylon tubes, prolonging service life and minimizing air leakage.

Key Features

Sealing System: Fast plugs sealed with liquid sealant.

Nylon Tubes: Replaced PU pipes for better durability.

Service Life: Extended due to improved sealing and material choices.

Energy Savings: Minimized air leakage reduces energy consumption.

Product Parameters

Sealant: Liquid sealant

Tubes: Nylon

Leakage: Minimal air leakage

Use Cases

EPS Foam Packaging: Ideal for producing high-quality foam packaging for fragile items.

Custom Molds: Suitable for creating custom molds for automotive parts, construction materials, and insulation.

Benefits for Businesses

Durability: Nylon tubes and liquid sealant ensure long-lasting performance.

Energy Efficiency: Minimized air leakage reduces energy consumption.

Reliability: Improved sealing ensures consistent and reliable operation.

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

Expansible polystyrene EPS expanded machineryOct,14,2024

Expansible polystyrene EPS expanded machineryOct,14,2024 -

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Links

Links