Comprehensive Features of the GB-SPZ1400-1750PT EPS Machine

Comprehensive Features of the GB-SPZ1400-1750PT EPS Machine

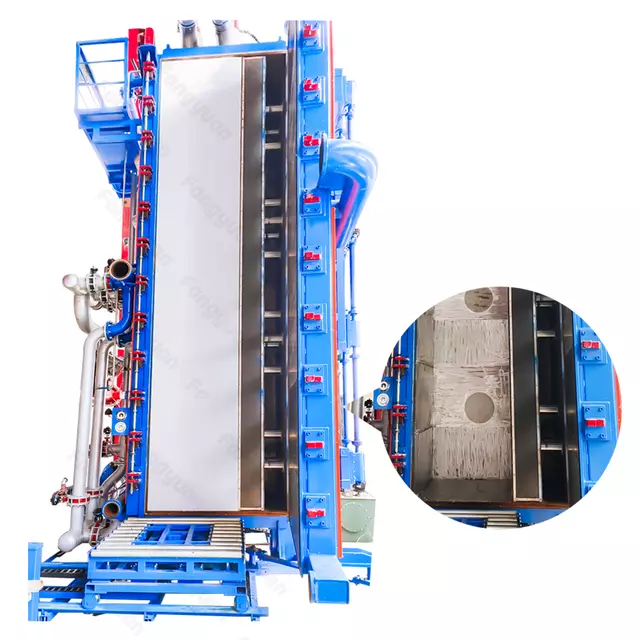

Overview

The GB-SPZ1400-1750PT EPS Machine is a comprehensive solution for EPS foam forming, combining advanced features to ensure high-quality and efficient production. From high-strength steel plates to advanced control systems, this EPS Machine is designed to meet the highest standards of performance and reliability.

Key Features

High-Strength Steel Plates: Ensure the highest level of stability and durability.

GP1000 Steam Reducer: Provides precise steam control.

Hot Zinc Coating: Protects against corrosion and ensures long-term reliability.

Sealing System: Minimizes air leakage and extends service life.

Dual Barrel: Produces EPS products of two different densities simultaneously.

PID Control: Ensures precise air and pressure settings.

Electrical Host and Stainless Steel Tray: Provide precise control and hygienic conditions.

Protection System: Ensures safe and seamless operation.

Water Cooling: Maintains optimal operating temperatures.

Product Parameters

Material: High-strength steel plates

Steam Reducer: GP1000

Coating: Hot zinc

Sealing: Liquid sealant, nylon tubes

Barrel Design: Dual

Control System: PID control, electrical host

Tray Material: Stainless steel

Protection System: For power off

Cooling System: Water cooling

Use Cases

EPS Foam Packaging: Ideal for producing high-quality foam packaging for fragile items.

Custom Molds: Suitable for creating custom molds for automotive parts, construction materials, and insulation.

Benefits for Businesses

Durability: High-strength steel plates and hot zinc coating ensure long-lasting performance.

Precision: Advanced control systems ensure accurate and consistent foam forming.

Reliability: Protection systems and temperature regulation ensure safe and continuous operation.

Versatility: Dual barrel design allows for simultaneous production of different density products.

Efficiency: Minimized air leakage and optimal operating temperatures reduce energy consumption.

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

Expansible polystyrene EPS expanded machineryOct,14,2024

Expansible polystyrene EPS expanded machineryOct,14,2024 -

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Links

Links