EPP Shape Machine: Crafting Expanded Polypropylene into Custom Shapes

EPP Shape Machine: Crafting Expanded Polypropylene into Custom Shapes

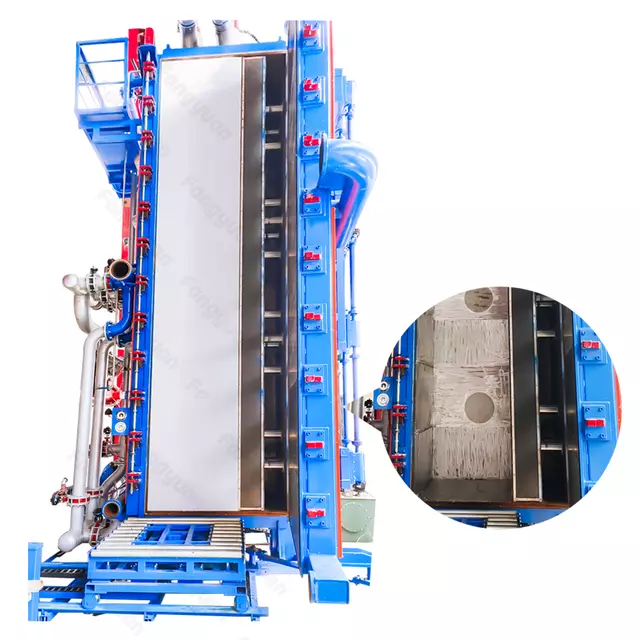

An EPP Shape Machine is designed to mold expanded polypropylene (EPP) beads into specific shapes through a combination of heating, injection, and cooling processes. This machine is highly versatile, allowing for the production of lightweight, durable, and resilient parts used in various industries such as automotive, packaging, and construction.

The process begins by heating the EPP beads, which expands them to their moldable state. After that, the beads are injected into a custom mold, taking the desired shape. Finally, the cooling process hardens the material, creating a solid and durable end product.

-

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024

EPS pre-expander with vacuum EPS Batch pre-expander granules machineOct,14,2024 -

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024

How an EPP Shape Machine Works to Mold Custom PartsOct,27,2024 -

Expanded polystyrene block making machine with AdjustableOct,14,2024

Expanded polystyrene block making machine with AdjustableOct,14,2024 -

Expansible polystyrene EPS expanded machineryOct,14,2024

Expansible polystyrene EPS expanded machineryOct,14,2024 -

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Fully Automatic Machine Producing EPS Block EPS Foaming Machine EPS Panel Production LineOct,14,2024

Links

Links